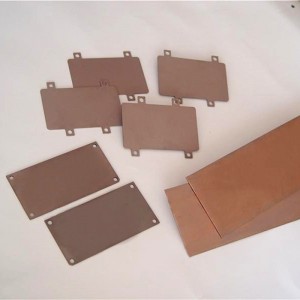

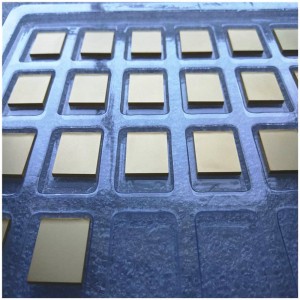

Tungsten Copper WCu Heat Sink

Kufotokozera

Tungsten copper electronic mackaging materials ali ndi mphamvu zowonjezera zotsika za tungsten komanso mawonekedwe apamwamba amafuta amkuwa. Chofunika kwambiri ndi chakuti matenthedwe ake kukula koyenelera ndi matenthedwe madutsidwe angapangidwe ndi kusintha zikuchokera zinthu anabweretsa yabwino kwambiri.

FOTMA imagwiritsa ntchito zopangira zoyera kwambiri komanso zapamwamba kwambiri, ndipo imapeza zida zoyika pakompyuta za WCu ndi zida zoyatsira kutentha zomwe zimagwira bwino ntchito pambuyo pa kukanikiza, kutentha kwambiri komanso kulowa mkati.

Ubwino wa Tungsten Copper (WCu) Electronic Packaging Materials

1. Tungsten zamkuwa zopangira zida zamagetsi zimakhala ndi mphamvu yowonjezera yowonjezera kutentha, yomwe ingagwirizane ndi magawo osiyanasiyana (monga: chitsulo chosapanga dzimbiri, valve alloy, silicon, gallium arsenide, gallium nitride, aluminium oxide, etc.);

2. Palibe sintering activation zinthu anawonjezera kukhala wabwino matenthedwe madutsidwe;

3. Low porosity ndi mpweya wabwino kuthina;

4. Kulamulira kwabwino kwa kukula, kutsirizitsa pamwamba ndi flatness.

5. Perekani pepala, magawo opangidwa, komanso amatha kukwaniritsa zosowa za electroplating.

Zida za Copper Tungsten Heat Sink

| Maphunziro a Zinthu | Tungsten Content Wt% | Kuchuluka kwa g/cm3 | Kukula kwamafuta × 10-6CTE (20 ℃) | Thermal Conductivity W/ (M·K) |

| 90 wc | 90±2% | 17.0 | 6.5 | 180 (25 ℃) /176 (100 ℃) |

| 85 wc | 85 ± 2% | 16.4 | 7.2 | 190 (25 ℃)/ 183 (100 ℃) |

| 80 wc | 80±2% | 15.65 | 8.3 | 200 (25 ℃) / 197 (100 ℃) |

| 75 wc | 75 ± 2% | 14.9 | 9.0 | 230 (25 ℃) / 220 (100 ℃) |

| 50 wc | 50±2% | 12.2 | 12.5 | 340 (25 ℃) / 310 (100 ℃) |

Kugwiritsa ntchito Tungsten Copper Heat Sinks

Zida zoyenera kulongedza ndi zida zamphamvu kwambiri, monga ma substrates, maelekitirodi otsika, ndi zina; mafelemu otsogolera apamwamba; matabwa owongolera kutentha ndi ma radiator a zida zankhondo ndi wamba zowongolera kutentha.